Identifying Offsite Emissions with Continuous Monitoring

By: Kathleen Jenkins

The problem with offsite emissions

In areas of high-density oil & gas, mixed-use industrial, and agricultural development, it can be difficult to determine the source of a greenhouse gas emission. If an emission from an offsite source is attributed to an operator’s site it can lead to:

Challenging landowner relations due to odor complaints

Employee and contractor HSE concerns due to H2S, VOCs, or other hazardous emissions

Operations and maintenance crews searching for emission sources that originated from an offsite source

Incorrect quantification of site-level emissions due to inclusion of offsite sources

Penalties due to Erroneous Super Emitter identification

There are two components to understanding the source of emissions using continuous monitoring.

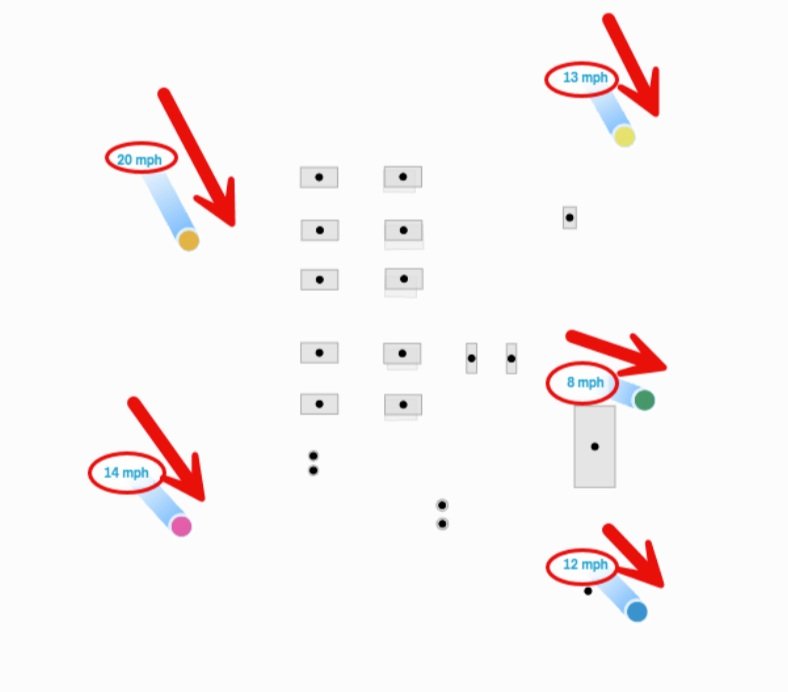

The first step is to collect a suitably rich set of wind data across the whole site - specifically, wind speed and direction. The data does not lie. In deployments of Qube's devices to our customers' sites, we have observed meaningful variance in wind data collected by devices that are less than 100m (300 ft) from each other (Figure 1). This is due to the topography of the site and its surrounding area as well as wind interactions with bluff bodies, such as large tanks or buildings that alter the air flow.

Figure 1 – Red arrows are showing the wind directions and wind speeds are circled. Data is from each device’s anemometer on one site.

Some continuous monitoring solutions deploy a single anemometer to sites, collecting a single source of wind speed and direction which results in a simplified representation of the wind vectors on a site. In figure 2, two possible emission sources are illustrated with red and blue circles. If a single wind data point is measured, it can be difficult to determine if the source is the red circle or the blue circle. When multiple wind measurements are collected, a more representative vector field can be modeled which improves confidence that an emission originated at the red circle.

Figure 2 – Left image showing assumed wind direction on a site one anemometer at device 1. Right image showing varying wind directions on a site with anemometers at each device.

In both panes, the red and blue circles are possible emission sources. The left pane shows a simplified wind vector array that results from a single wind measurement. The right pane shows how the vector field can change with more measured data due to anemometers at each device.

It is easy to imagine a situation where field operators & contractors are asked to confirm a leak identified by a continuous emissions monitoring system using an Optical Gas Imaging (OGI) camera. They struggle to find an emission source where a wind vector array localizes to incorrect equipment on site or incorrectly classifies an emission as originating onsite. Chasing false positive emissions costs companies time and money. By collecting additional wind data, field operators and contractors can more efficiently confirm and repair leaks.

The second component to understanding offsite emissions is incorporating measured gas concentrations, wind speed, and wind directions into software algorithms. The focus of this post is on the filtering of emissions - so we will leave detailed discussion about localizing and site-rate calculations for another day.

By comparing gas concentration to the wind direction, carefully designed software algorithms determine if gas arrived at the sensor from an onsite or offsite source. For example, in Figure 3 we see how measuring wind direction at multiple locations allows for the determination of whether a particular emission likely originated onsite (inside the yellow border) or if it originated at an offsite source (inside the red border).

Figure 3 – Offsite Emission

In this image, there is an emission at the neighboring tank facility. Qube devices are colored circles. The wind is blowing from the southeast direction as seen with the blue arrow. As the wind blows the red emission plume from the neighboring tank site, it travels over the pink device in the southeast corner and the increase in methane is identified at the pink device. As the plume is blown further across the site, in the cone of dispersion, the methane change is identified at the other devices in the northeast side of area being monitored. By measuring the angle and of the wind at all the devices, Qube can confidently determine that the detected emission originated offsite. Any emission volume is then filtered out of emission quantification for the area being monitored.

With the attention to Super Emitter events, the information about off-site emissions can be very valuable. As the satellites report what they detect, a plume may be identified on a site similar to the image above in Figure 3. Having data that can show when the emission began as well as the direction of the wind at the time of the satellite image can help to eliminate fees due to a neighboring facility’s emission.

A common landowner relations problem that many companies face is odor complaints from adjacent landowners and residents. These complaints are particularly prevalent for landfills and RNG anaerobic digestion lagoons as well as areas of high-density oil development where multiple oil and gas operators have drilled wells and constructed production facilities.

Landowners and residents can be quick to blame immediately adjacent production facilities for any unpleasant odors that the wind blows to their residence. Continuous monitoring companies improve landowner relations by providing valuable air quality data that can be directly used in landowner communications. If a leak is determined to have originated offsite, this can be communicated to a neighboring landowner.

Additionally, implementing continuous monitoring for gases such as VOCs and H2S can help companies be aware of potential HSE issues related to employees’ and contractors’ exposure to these harmful gases. Knowing and identifying an emissions source is the first step. VOC and H2S exposure should be minimized with properly operated equipment; however, operating conditions can change, equipment may fail outside of expected maintenance windows, and adjacent production facilities may not be operated to the same standard.

Qube’s Continuous Monitoring Solution

The Qube Solution combines on-site devices with cloud analytics and dashboards to effectively detect, quantify, and manage offsite emissions sources.

Each Qube device is fitted with individual anemometers (wind speed and direction) allowing for the creation of a more sophisticated wind vector mesh and providing greater certainty to the origin of a particular emission. Field measured gas concentrations, wind speed & direction, temperature, humidity, and barometric pressure are fed from each device into Qube’s dashboards, allowing customers to filter emissions as originating onsite or offsite, localize emissions to equipment groupings, and compute site-wide emission rates. Offsite emissions are omitted from total site-rate calculations.

By deploying continuous emissions measurement systems such as Qube's devices to their production facilities, leading oil & gas operators are able to:

Measure what matters by filtering out offsite emissions from site-specific emissions quantifications.

Deploy maintenance crews with trust that an alert generated by the Qube platform is a result of an onsite source. No more chasing false positive detections.

Improve stakeholder relations by collecting definitive data regarding emissions from your facility.

Respond confidently if contacted about a Super Emitter Event.