Continuous Emissions Monitoring at Landfills: An Overview

Author: Ben Montgomery, Jarett Henry

TL;DR

Methane is a potent greenhouse gas produced in significant quantities at landfills from the decomposition of organic material.

Regulatory frameworks in Canada and the USA are evolving to address these emissions, including stringent monitoring and leak detection requirements.

Continuous monitoring solutions, like Qube, offer numerous benefits for landfill operators, but there are also unique challenges that an effective emissions monitoring product must address to ensure accurate, precise, and timely performance in this space.

Methane is a potent greenhouse gas – roughly 28 times more impactful than carbon dioxide (CO2) and efforts to monitor and reduce these emissions across all industries are essential (1). The atmospheric burden of methane has rapidly increased in the last few decades. About 11% of global methane emissions come from landfills, specifically from the decomposition of organic material such as food scraps, yard waste, and paper (2). Methane is the largest component of landfill gas – between 45-60% (3). In Canada, municipal solid waste landfills account for about 23% of the country’s methane emissions (4). In the USA, landfills are the third-largest source of human-related methane emissions, accounting for almost 18% (5). As significant sources of methane emissions in North America, landfills are a growing concern for environmental agencies and regulatory bodies. This article explores the unique challenges landfill operators face in monitoring and managing emissions due to varying weather and topography, operational constraints, and regulatory requirements.

Regulatory Landscape for Landfill Methane Emissions in North America

Following the increased scrutiny on methane emissions due to their impact on climate change, governments across the world are looking to increase the stringency of their landfill regulatory requirements and limits, and Canada and the USA are no exception.

Canada

In Canada, methane is included in the Schedule 1 – List of Toxic Substances of the Canada Environmental Protection Act (CEPA). Currently, British Columbia (6), Alberta (7), Ontario (8) and Quebec (9) have regulations requiring larger closed landfills to capture and control or reduce methane emissions. The federal government has proposed new legislation, stating that “a consistent and more stringent regulatory approach is needed to reduce landfill methane emissions across the country” (10, 11). The proposed draft estimated that 146 landfills would be included in the prescribed requirements for surface emissions monitoring (SEM), leak detection and repair of landfill gas equipment, and monitoring the vacuum pressure of gas collection wells.

USA

In contrast to Canada, there is existing federal landfill methane legislation through the Environmental Protection Agency (EPA)(12). These requirements are complemented and strengthened by additional regulations in states such as California (13), Oregon (14), Washington (15), and Maryland (16). More changes are coming on the horizon, as both the EPA (17) and California (18) have announced plans to introduce more stringent regulations, while Colorado is in the process of creating their first state-wide regulations (19). These new regulations are expected to address the limitations of traditional SEM approaches by incorporating advanced monitoring technologies such as continuous monitoring (20).

Limitations of Traditional Approaches to Surface Emissions Monitoring (SEM) at Landfills

Traditional SEM approaches, as required by current regulations, involve periodic sampling of the methane concentration at discrete points in the landfill. These are typically conducted through walking surveys (“Method 21”) or drone-based methods (“OTM-51”) (21, 22). While these approaches can detect leaks under the right circumstances, they also have several meaningful limitations:

Delayed mitigation

Surveying the landfill surface only 3-4 times per year means that significant leaks may go undetected for long periods of time, releasing large volumes of methane into the atmosphere. This is particularly impactful for landfills that collect and sell their landfill gas for electricity or RNG

Coverage

Reliance on a probe <10 cm from the surface results in an inability to survey the active/working face and any dangerous areas

Measuring concentration instead of volume

Methane concentration in any given location is heavily influenced by wind speed. As a result, the number of exceedances (>500 ppm for EPA) detected by an SEM survey depends on the current wind conditions and may not reflect actual emission volume

Environmental variability:

Wind, temperature, and precipitation can all disrupt the suitability of traditional SEM when surveys are scheduled

Diurnal variation

Traditional SEM only takes place during daytime hours. Measuring at night can provide critical insights, such as the effectiveness of various cover materials placed over the active/working face at the end of each day

Safety

Even when SEM surveys are rescheduled to avoid extreme environmental conditions, Method-21 still requires individuals to walk significant distances through hilly terrain amidst heavy construction equipment

The cumulative impact of these limitations has been highlighted by a recent analysis of EPA landfill inspection reports by Industrious Labs (23). It’s important to note that the findings below all come from landfills that are conducting their SEM surveys at the required intervals for regulatory compliance:

96% of landfills had at least one exceedance, with a total of 711 exceedances across the 29 landfills in the research sample

48% of landfills had multiple exceedances despite previously reporting few or no exceedances

The study concluded that “…these regulations allow emissions monitoring practices that are spotty, vulnerable to human error and pose safety threats to landfill inspectors”

Benefits of Deploying Qube’s Continuous Monitoring Devices at Landfills

While continuous monitoring technologies such as Qube are continuing to develop their solution for landfills, they directly address many limitations of traditional SEM approaches. This includes real-time leak detection, day and night coverage of the entire landfill, volume-based measurement, and year-round monitoring through varying environmental conditions.

However, not all continuous monitoring systems are alike, and Qube devices have several distinct advantages:

Advanced detection algorithm

Qube devices utilize a physics-based air dispersion model that can detect, localize, and quantify methane leaks as small as 0.1 kg/hr at a 100m distance. And with our controlled release testing facility – the only one of its kind in the industry – our data science team is continually iterating and improving our capabilities

Cost-effective scale:

Having an accurate technology is one thing, having a low enough cost to cover hundreds of acres across a landfill surface is another. Qube devices cost significantly less than comparative products, enabling cost-effective deployment at scale

Manage odors and build trust with neighbors:

Detect and address sources of additional gases (H2S, NO2, SO2, etc.) before they become a problem. Utilize the data on wind speed and direction from each device’s anemometer to triangulate where odors are coming from, or to demonstrate when they’re coming from outside the landfill

Reliability in all conditions:

Qube devices have been deployed effectively from Northern Canada to the Middle East, with an operating temperature range of -40 oC to +60 oC. They are powered by solar panels and can last over seven days without sunlight. Our software platform contains automated anomaly detection and over-the-air calibration and fixes, with trained field technicians available if needed

Unique Challenges of Deploying Continuous Monitoring at Landfills

Most advanced monitoring technologies were originally developed for the oil and gas industry, including continuous monitoring systems like Qube. While some aspects of these technologies can be applied directly to landfills, there are several unique challenges that need to be addressed.

Variable topography

In contrast to oil and gas sites with relatively flat ground, landfills contain complex topography with multiple slopes. This variability affects the dispersion of methane that localization and quantification algorithms are built upon. To address this, Qube creates a “sub-site” for each major slope, allowing the algorithm to run separately for each group of devices. Different alarm thresholds can be set for each “sub-site”, allowing operators to customize alert notifications based on actionable emission rates for that area.

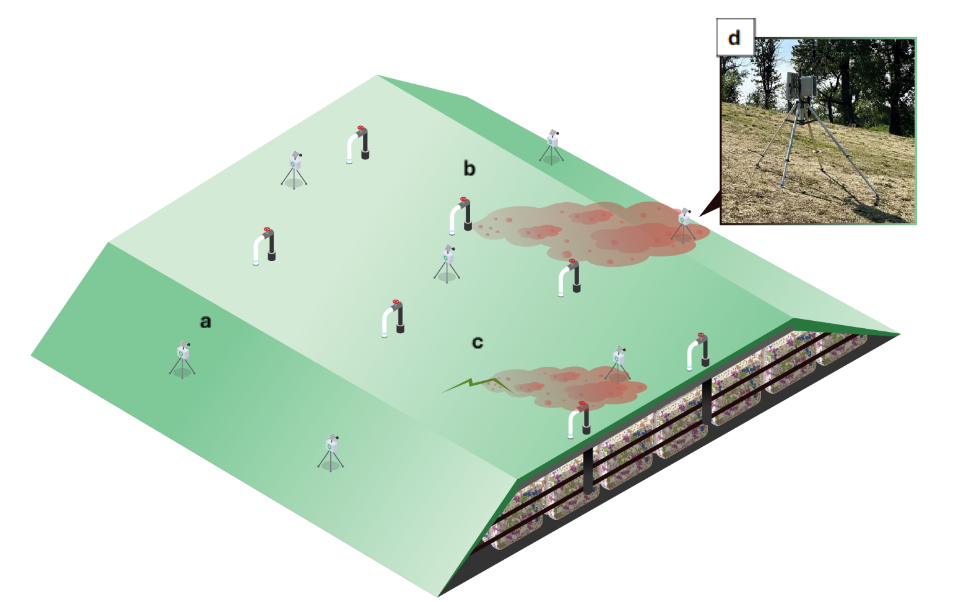

Figure 1. A schematic deployment of Qube’s continuous monitoring devices within a landfill (not to scale). Qube devices (a) are deployed around the perimeter and on the surface of the landfill. Emissions may escape through leaks at the wellhead (b), from areas with inadequate cover (c), or from the active/working face (not shown). Qube devices detect the emission plumes and report to operators via the Qube dashboard. Panel d shows a Qube device securely deployed on a slope.

Diffuse emission sources

While methane emissions from other industries tend to come from discrete “point” sources, landfills have a mix of point sources and diffuse “area” sources (e.g., uncovered portions of the active face). The air dispersion of these methane plumes behaves differently, requiring a different approach to the physics-based modelling. Qube is currently finalizing an update to our algorithm that addresses this challenge.

Multiple ongoing emission sources

Most methane monitoring technologies were built on identifying the single most likely source and attributing all site-wide emissions to it. This works well in industries such as oil and gas where it’s unlikely to have more than one major leak at a time, but landfills often have multiple “hot spots” releasing methane for long durations. Qube is developing a multi-source model address this issue, which will allow users to see estimated locations and quantities of all probable source locations simultaneously.

Deploying devices inside the landfill perimeter

Given the size of landfills, fenceline deployments around the site perimeter would result in devices being up to 500m away from potential sources. When devices are this far away, there can be a significant number of upwind sources that Qube’s algorithm could localize to. As distance from source is a key variable in the quantification calculation, this increases the risk of inaccurate estimates. To better differentiate between potential upwind sources, devices need to be placed within the landfill itself. However, this creates a new challenge for ground-based systems, as mounting posts cannot be drilled into the ground due to their impact on the intermediate or final cover. Adding to this challenge, typical stands designed for flat ground are unstable on the steep and uneven landfill slopes. To remedy this, Qube has designed a new stand tailored specifically to remaining stable and level on even the most difficult surfaces.

Conclusion

The landfill sector is undergoing significant change – heightened public scrutiny, incoming regulatory changes, and a rapidly evolving emissions monitoring landscape. Continuous monitoring technologies such as Qube offer clear advantages over traditional SEM approaches, including real-time leak detection, odor management, and all-season coverage. However, landfill deployments present unique challenges compared to traditional oil and gas sites, giving Qube an exciting opportunity to innovate and deliver tailored solutions that address the specific needs of this dynamic environment.

Contact Qube today for more information on our product development journey. We are always looking for more opportunities to pilot and learn together with our customers!